powder coat impact test|powder coating testing : wholesaling When applied correctly, powder coating is a versatile and durable finish that offers many benefits such as its ability to withstand abrasion, scratches, and marring. This article will . 27 imóveis ao buscar Kitnets em Castanhal no Pará. Ordena.

{plog:ftitle_list}

webA Air France está comemorando 90 anos de elegância. Desde sua fundação, a Air France celebra a arte de viver à la française (à francesa), esse "je ne sais quoi" francês .

Quality of powder coatings has been defined as: powder which conforms to agreed upon performance standards. Quality products can be assured by using the three C's: cooperation, communication and coordination. The finished powder should be checked upon delivery, . You can perform the impact test to assess your powder coating’s adhesion and determine how well it holds up in high-stress environments. This test is also destructive, so prepare a separate panel and place it into an . Impact Test. Similar to the mandrel bend test, the impact test deforms a sample panel in order to test the adhesion of the powder coating. The sample panel is placed into the .

When applied correctly, powder coating is a versatile and durable finish that offers many benefits such as its ability to withstand abrasion, scratches, and marring. This article will .

A coating thickness test that accurately measure your coating application over wood, concrete, plastics or composites will let you know whether the powder coating has been applied to the . Information on current test procedures for pipe and reinforced steel bar coating powders and powder coatings can be obtained through their respective ASTM .

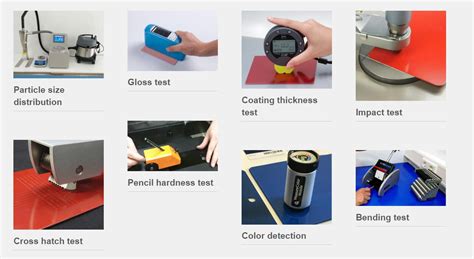

Powder coating testing is designed for two purposes: Performance reliability, (i.e.,to determine the suitability of a coating for a given use.) Quality control, (i.e., to maintain .

3. Impact test. You can perform the impact test to assess your powder coating’s adhesion and determine how well it holds up in high-stress environments. This test is also destructive, so prepare a separate panel and . The impact fusion is hard to clean out. We run 10 automatic guns and two manual guns in a system that is designed to run at 12 fpm. We think we have a powder problem, but our supplier says our delivery pressures are too high. Any ideas for ways to control impact fusion would be appreciated. How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

The Impact Tester is a widely used device for the coating and plastic industries. In both industries impact resistance is measured by a falling weight from a. Powder coating testing is primarily does using ASTM standards. ASTM has several standard test available for powder coaters to measure powder coating quality. . IMPACT TEST . Coating on .036 inch thick phosphated steel panel shall withstand impact with 1/2″ Gardener impact tester ball at 26 inch pounds direct and reverse. No grazing or loss . Test powder compatibility with the metal using cross-cut or X-hatch adhesion tests before a full production coating run. . Additionally, proper ventilation and air circulation can aid in minimizing the impact of humidity on the powder .

Powder Coating testing instruments and services. Find suppliers of testing instruments to do your own testing or testing service suppliers to do it for you. Showcase; . coating thickness, hardness, drying time, water permeability and impact resistance. 9104 Guilford Road Columbia, MD 21046 Toll free: 800-343-7721 . Powder Coating Adhesion Testing. Adhesion testing measures how well the powder sticks to the part once it is fully cured. As with the cure test, your adhesion test results can be affected by overbake or underbake.Generally, adhesion testing kits are available for specific testing requirements.Heat-sensitive carbon fiber tubes coated with a UV curable powder coating. Powder coating is a type of coating that is applied as a free-flowing, dry powder.Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a .

A. Impact Resistance is typically a "formulated" property. It is tested on ACT or Q panels in the powder coat manufacturers lab, and the test usually has no use at the point of application due to varying substrate composition and thickness. 4.1 This guide provides a useful summary to the selection and use of procedures for testing coating powders and powder coatings. It is applicable to both thermoplastic and thermoset coatings, unless indicated otherwise. By design this guide does not purport to address test methods or procedures developed specifically for the functional powder coating market, .

IS 13871 (1993): Powder Coatings [CHD 20: Paints, Varnishes and Related Products] IS 13871 : 1993 mm 9T3zx +s;r - f%fqf+ Indian Standard POWDER COATINGS- SPECIFICATION . Erichsen test, mm \ Impact resistanoe (direct/reverse), kg/cm Protection against corrosion, 1 000 h 50-60 microns unless specified otherwise SmoothObtaining Good Impact Resistance in Coatings To obtain good impact resistance in coatings, the paint film must consist of a polymer that has a sufficiently high molecular weight to have strong intermolecular entanglement (and therefore, high tensile strength). At the same time, paint should have sufficiently low viscosity (by choice of proper molecular constituents and limiting .The most widely used is the "water break free" test. This test is a visual observation of whether water fully sheets over the clean part or draws away from portions of the surface (like water on a waxed car). . It can be used with almost any substrate. Powder coatings will often give improved performance compared to liquid paint over the same .Bulky edges in powder coating may stem from various factors within the application process, leading to uneven and non-uniform coatings that detract from the overall quality of the finished product. Uneven Powder Distribution: Inconsistent distribution of the powder material across the surface causes bulky edges.

IMPACT TEST SP1880, SP1890, SP1891, SP1895 1 SAFETY PRECAUTIONS The Impact Test has been designed to be as safe as possible. However as with all . Zero the instrument on the sample that is the test object (test sample with coating layer downwards). 10. Hold the guide tube while releasing it by turning the handle [ 6 ]. In terms of environmental impact and safety, powder coating stands out. It’s considered more environmentally friendly than traditional paint due to its minimal production of VOCs and lack of solvents. Compared to solvent-based paints, powder coating substantially reduces finishing line emissions, resulting in fewer harmful environmental by .Leaders in Industrial Fusion Bonded Powder Coating Since 1967 Since 1967 Fusecote has focused it's expertise in serving the industrial sector, applying only 100% virgin powder on parts.

2006. Q. Powder peels off! I would like to know how to inspect a finished powder coated part and tell if part is 100 percent perfect to ship. I would have times when I think the part is perfect and I would put a decal sticker on the part and if I peeled the sticker off to relocate the sticker it would peel the powder off.Learn how to achieve a flawless finish for your powder coating applications. Our technical videos offer expert tips and demos on powder. Skip to main content. [email protected]. 940-668-1062. . Powder coating pencil hardness test. Powder picture framing and how to resolve. Powder Coating - fail impact test (160 in-lbs) and Salt Fog Test 500hrs. I have problem to get my sample panel to pass the above requirement after powder coating. Before coating we had applied required stages of pre-treatment including Zinc Phosphating. The base material used is GI (Galvanized Iron) without chromate. Impact test as per ASTM D2794.

Find here Impact Testers, Impact Testing Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Impact Testers, Impact Testing Machine across India.Impact test for Powder Coating. Impact testing is a crucial evaluation method for assessing the durability and resilience of powder coatings. This test involves subjecting coated materials to controlled impacts, simulating real-world conditions and potential stresses. By measuring the coating’s ability to resist cracking, chipping, or .

Impact Testing. SKYCOAT uses the Elcometer 1615 Variable Impact Tester for evaluating the resistance of a coating to impact (elongation, cracking or peeling). Impact testing is performed according to ASTM D2794-93 (2010) standard. After testing the durability of powder coating, spray paint, and unfinished metal, we have seen, conclusively, that powder coating is more durable than the others by an order of magnitude. It is designed to literally stand the test of time, keeping your parts sealed away from the elements, as well as protecting them from high impact and high .The test standards used for impact resistance testing include: ASTM D2794 – Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact) ASTM G14 – Standard Test Method for Impact Resistance of Pipeline Coatings (Falling Weight Test) ISO 6272 – Paints and Varnishes - Rapid-deformation (Impact Resistance .

powder coating testing

powder coating rub test

powder coating measurements

webNot64 is a port of the Nintendo 64 emulator, Wii64. This emulator allows you to play Nintendo 64 games on their Wii console, providing a way to enjoy classic games from the past. Not64 is known for its high .

powder coat impact test|powder coating testing